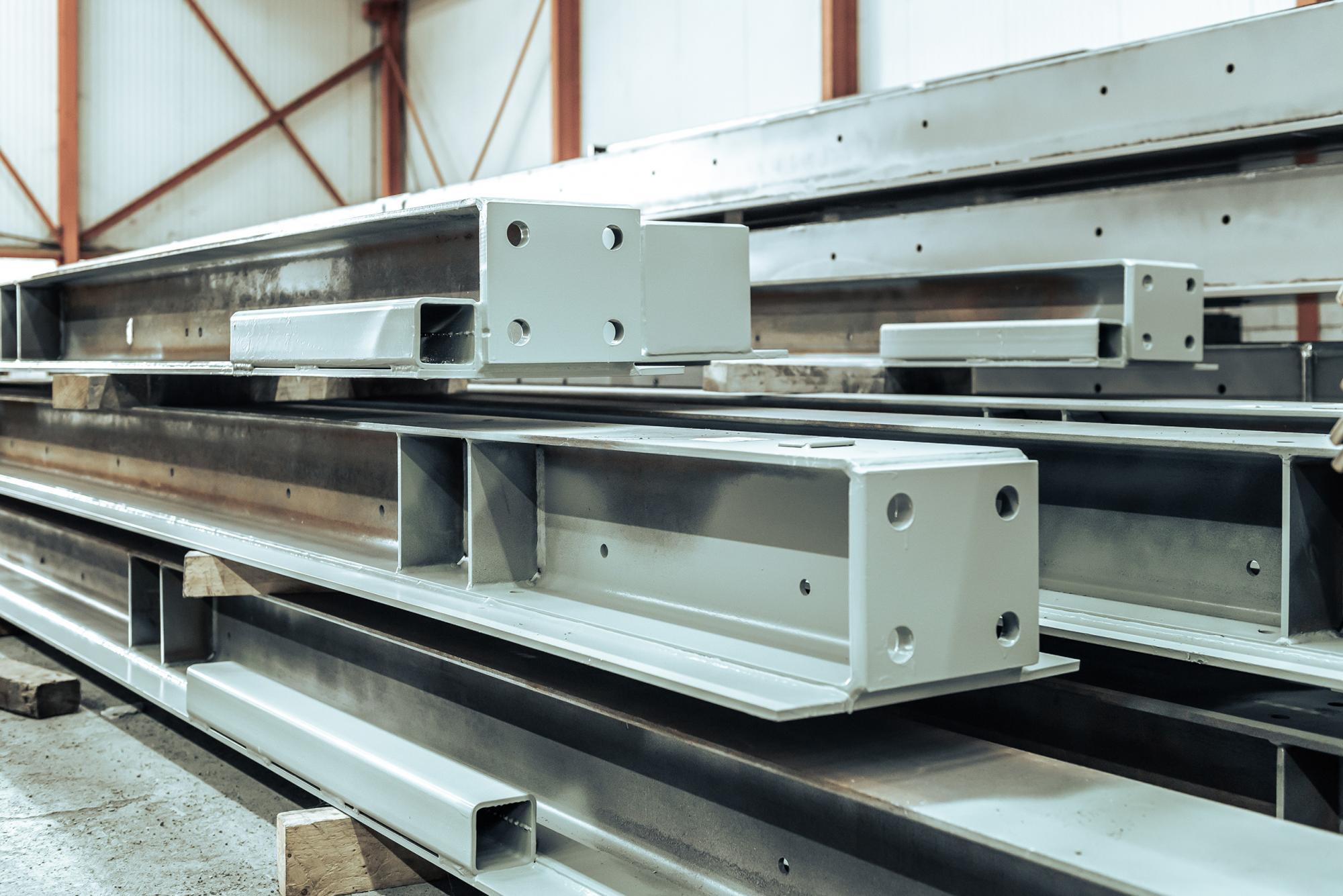

SFB beams are easier to produce

As SFB ('Slim Floor Beam') beams have an open structure, production is simpler than with closed beams such as the top-hat and cap variant. The SFB beams produced by Mouw Hoedliggers are particularly suitable for the installation of floor panels.

Fire-resistant treatment not always necessary

This type of beam is made by welding a wide strip of steel under a standard profile. The heads of the hollow-core slabs then connect to the plates of the profile. To create a bond in the floor, the hollow spaces on the sides of the profile are filled with concrete.

SFB beams do require a fire protection treatment, unless reinforcing bars are also placed in the hollow space; this already gives the structure better protection in the event of a fire.

The torsion of an SFB beam is less strong than that of cap or top-hat beams. In some cases, this can cause problems when installing hollow-core slabs. As SFB beams are not generally exposed to considerable tensile forces, the product is made in S235 steel as a standard, unless another grade is requested.

For SFB beams, profiles from the UK UC series or the European IPE, HE-A, HE-B and HE-M beams are used.

The main advantages of SFB beams are:

- Lightweight construction

- Simple, but sometimes unnecessary treatment

- Low construction height

- Environmentally conscious

The beams of Composite Steel Beams

-

Sigma Beam

The Sigma Beam is the Composite steel beam of the future

Discover the advantages -

Top-hat beams

Ideal for prefabricated floor panels as more space is available in floor height

View our top-hat beams -

Castellated beams

For large spans with limited load

Read about our castellated beams -

Cap beams

For prefab floor elements at the edge of the structure

View our cap beams -

IFB Beams

Lighter and therefore more cost efficient

View the advantages -

SFB Beams

Install floor elements easier with this open beam

Read more about the SFB beams